Research & Innovation

Continuous Investment into R&D

Spark Transducers continuously invests in research and development so we can provide cutting edge transducer solutions to our customers.

Current activities encompass research into modelling, micro-fabrication, materials and advanced fabrication processes required for manufacture of high-frequency ultrasonic transducers.

Transducer Design

- Finite element modelling to evaluate and optimise the overall acoustic performance of individual transducer elements as well as the complete transducer array.

- Design of matching and backing layers to improve bandwidth and acoustic coupling.

- Examples: 2D array for weld inspection, cylindrical array for underwater communications.

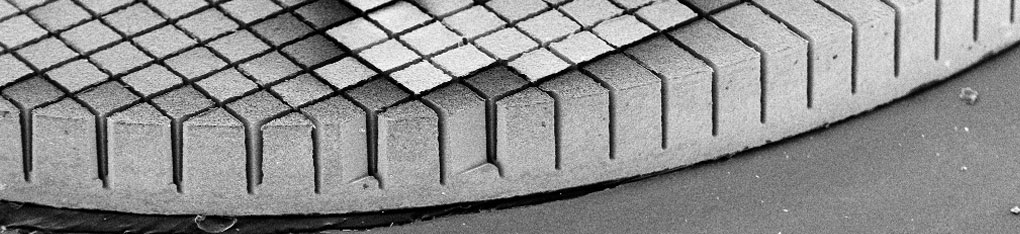

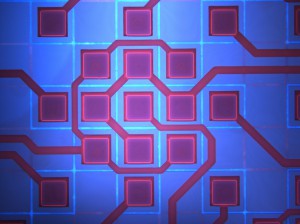

Piezo-composite Array Transducer Fabrication

- Fabrication of novel interconnects and passive materials for high-frequency linear, annular and 2D arrays. High density interconnects and small scale features can be fabricated using state of the art equipment in our clean room and micro fabrication facility – not possible with conventional techniques.

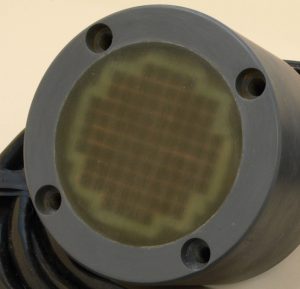

- Prototyping and production of complete interconnected arrays, assembled into custom made housings.

- We have the latest equipment for manufacturing precision ceramic and piezo-composites. We are able to grind, lap, dice, etch, and shape all types of materials to extremely tight tolerances.

- We regularly carry out in-depth materials characterization in order to address complex issues.

- We are continuously researching new materials and refining our innovative fabrication processes so we can deliver the highest quality transducers to our customers.

High-frequency Ultrasonic Testing

- We are equipped with the latest precision testing equipment so we can enforce strict quality controls throughout our operations; from initial materials inspection through to final analysis before our products are shipped.

Piezo ceramic Transducer Manufacturing

- Prototyping and manufacturing of custom single or multi-element transducers from bulk piezo ceramic plates, rings, cylinders or other shapes. Quality bonding of matching layer and backing material ensures consistent acoustic performance and durability. Enclosures and encapsulation protects the transducer while providing coupling to e.g. water.